Screw pump’s working principle and application

Screw pump is a positive displacement rotor pump, it is dependent on the screw and bushing formed by the volume of the sealed cavity to suction and discharge liquid. It is characterized by stable flow, small pressure pulsation, self-priming ability, low noise, high efficiency, long life, reliable work; And its outstanding advantages are not the formation of eddy current transport medium, the viscosity of the medium is not sensitive, can transport high viscosity medium.

The working principle of BZ screw pump is: when the screw pump works, the liquid is inhaled into the screw and pump shell enclosed by the seal space, when the active screw rotation, screw pump seal volume under the screw teeth extrusion to increase the screw pump pressure, and move along the axis. Since the screw rotates at constant speed, the liquid flow rate is uniform.

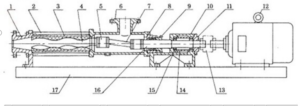

| 1 | Outlet | 7 | Connecting shaft | 13 | Coupling |

| 2 | Pull rod | 8 | Packed bed | 14 | Axle sleeve |

| 3 | Stator | 9 | Stuffing box gland | 15 | Bearing |

| 4 | Screw shaft | 10 | Bearing pedestal | 16 | Transmission shaft |

| 5 | Universal joint assembly | 11 | Bearing cap | 17 | Pedestal |

| 6 | inlet | 12 | Adjustable-speed motor |

BZ Screw pump is widely used in environmental protection, Marine industry, petroleum industry, medicine, daily chemical industry, brewing industry, construction industry, mining industry, chemical industry, printing and papermaking industry.