BZ Solids Control Sludge Dewatering Decanter Centrifuge

BZ Solids Control sludge dewatering centrifuge is a solid-liquid separation two-phase centrifuge. It is mainly used to realize the dehydration and solidification of sludge in different industries, and realize the two-phase separation of sludge and water. This article mainly introduces: the working principle of BZ Solids Control sludge dewatering centrifuge, the process flow of BZ Solids Control sludge dewatering centrifuge and the advantages and disadvantages of BZ Solids Control sludge dewatering centrifuge.

BZ Solids Control sludge dewatering centrifuge working principle

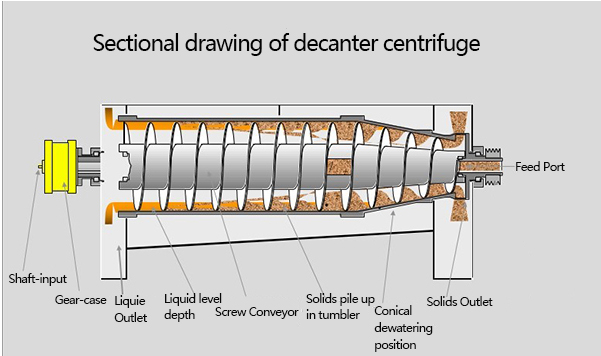

After the sludge is sent into the drum by the hollow shaft, it is immediately thrown into the drum cavity under the action of the centrifugal force generated by the high-speed rotation. The sludge particles have high density and high centrifugal force, so they are thrown onto the inner wall of the drum to form a solid ring layer; because of the low density and low centrifugal force, the water can only form a liquid ring layer inside the solid ring layer. The sludge in the solid ring layer is transported to the cone end of the drum under the slow push of the screw conveyor, and is continuously discharged through the outlet around the drum; the liquid in the liquid ring layer is continuously “overflowed” from the weir to the drum. In addition, the separated liquid is formed, and then collected and discharged out of the dehydrator by gravity.

BZ Solids Control sludge dewatering centrifuge process flow

The precipitated sludge from the sludge thickening tank is crushed by the sludge cutter, transported by the sludge feed pump, measured by the electromagnetic flowmeter, and combined with the prepared chemical solution sent by the flocculant dosing system. Mixed into the centrifugal dewatering machine; the sludge is separated into solid/liquid two-phase by the BZ dewatering machine, the liquid phase (clarified liquid or separated liquid) is directly discharged or returned to the sedimentation tank, and the solid phase (dewatered sludge) is conveyed by the BZ screw The machine is discharged to the transportation vehicle for transportation.

In the automatic dosing system of the flocculant, the powdery flocculant is added from the hopper (material feeder), and added to the preparation tank by the automatic powder feeding device (the colloidal flocculant is directly added to the preparation tank with a metering pump); at the same time, the tap water flows through the flow The meter enters the preparation tank and automatically prepares a solution with a certain concentration (about 0.08–0.15%); the prepared solution flows into the drug storage tank and is delivered by the dosing screw pump. After being measured by the electromagnetic flowmeter, it passes through the manifold (or static Mixer) mixed with the sludge from the sludge thickening tank and the centrifugal force brought by the high-speed rotation of the centrifuge, so that the dense material (solid phase) in the suspension entering the drum is affected by the centrifugal force and centrifugal pressure The sedimentation and separation will enter the dewatering machine for sludge dewatering.

BZ Solids Control sludge dewatering centrifuge advantages and disadvantages

Advantages of BZ Solids Control sludge dewatering centrifuge: compact structure, less auxiliary equipment, less land occupation; high solid recovery rate, low separation liquid turbidity; operation in a closed condition, sanitary working environment, low odor; no filter medium is required , Convenient operation and maintenance, high degree of automation; It is especially important that no or less chemical conditioning agent can be added. Although its power cost is higher, the total operating cost is lower.

Disadvantages of BZ Solids Control sludge dewatering centrifuge: The noise of this dewatering machine is generally large, and the moisture content of the sludge after dewatering is relatively high. When the difference in solid-liquid density is small, it is not easy to separate. If the sludge contains sand and gravel, it is easy to grind the centrifuge fluid and damage the equipment.